Aviation Fuel Supply Business

San-Ai Obbli’s hydrant system which supports Haneda Airport

In 1955, San-Ai Obbli developed the first hydrant system in Japan, which pumps aviation fuel to the aircraft through an underground pipeline, and began aircraft refueling operation at Haneda Airport.

Since then, our fuel facility and hydrant system technologies have been the model for major airports in Japan including New Chitose (CTS), Narita (NRT), Chubu (NGO), and Kansai (KIX), as well as several overseas airports such as Suwannaphum (BKK), Don Mueang (DMK), and Noi Bai (HAN).

In October 2010, we expanded the hydrant system, added fuel storage tanks, and constructed a new berth where large oil tankers can dock to deal with the growing demand arising from the opening of a new runway and international terminal at Haneda Airport. We will continue to build a safer and more reliable aircraft refueling system to meet a growing demand by the continuously developing Haneda Airport.

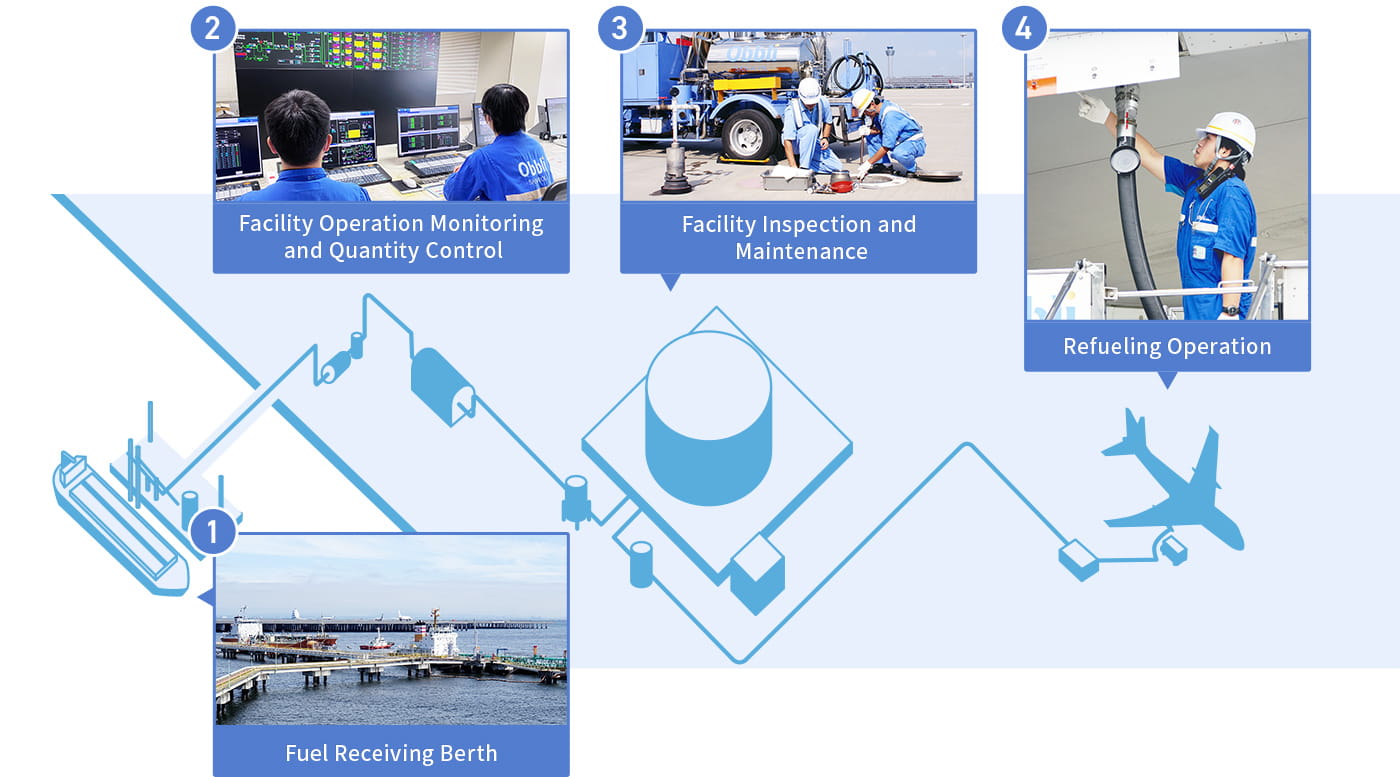

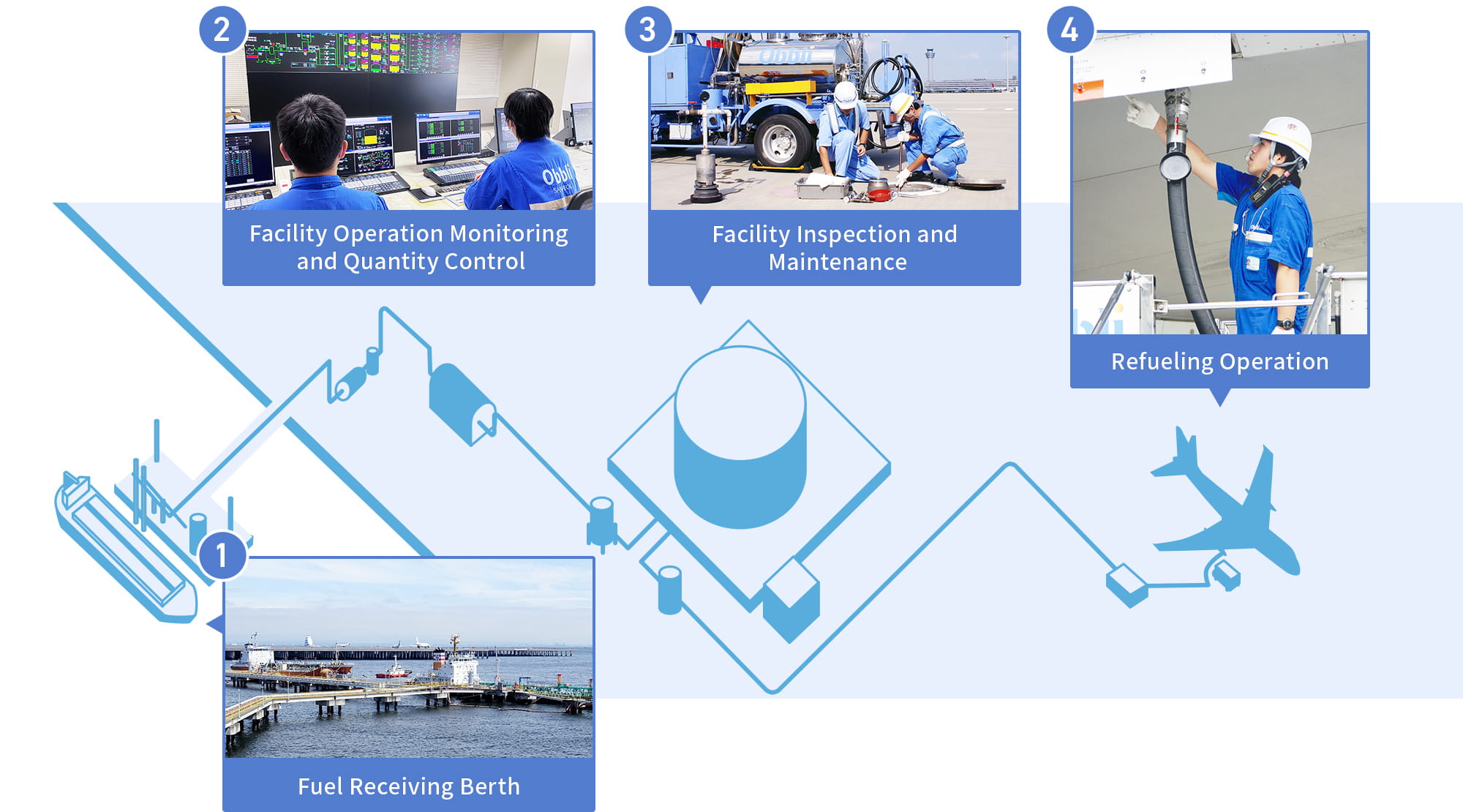

Flow from aviation fuel reception to refueling

The most important requirement for the process from aviation fuel reception to delivery is an accurate and prompt operation system based on safety. At Haneda Airport, our facility operation, quality control, and inventory control are performed efficiently and reliably by a 24-hour computerized facility control system and with supervision by human operators.

1 Fuel Receiving Berth

Aviation fuel received from a tanker at the berth is delivered to an oil storage tank with a tanker pump. Prior to fuel reception, we check a variety of documents, and perform thorough quality control, such as visual inspection, and inspection of moisture content, density, and electric conductivity, then taking a sample, and confirming the quantity of unloaded fuel.

We also regularly conduct safety drills including oil fence deployment and fire drills that simulate an accident during the unloading process.

2 Facility Operation Monitoring and Quantity Control

Aviation fuel in a storage tank that has passed quality testing is delivered to the aircraft using a dedicated pump.

The process covering the reception jetty through oil storage tank to aircraft refueling is controlled with computers, and the operator monitors to ensure that the system is running properly and operates the devices.

We perform daily routine inventory and quality management of aviation fuel.

In addition, we prepare for emergencies by conducting a variety of drills to be able to respond to an aviation fuel leakage accident or a large earthquake.

3 Facility Inspection and Maintenance

We maintain and inspect the hydrant system and related equipment periodically to prevent a malfunction or failure. Specifically, we inspect more than 320 hydrant pits in the apron areas at the airport every day, and periodically inspect the fuel storage tanks, the pressure of underground pipelines, and the substation facility under a variety of laws and regulations such as the Fire Service Act to ensure safe facility operation. We also periodically inspect 32 refueling vehicles, 8 special vehicles, and 25 maintenance vehicles, and make repairs when necessary.

4 Refueling Operation

Aviation fuel is delivered from a storage oil tank to each apron through an underground pipeline and pumped into the aircraft through a refueling vehicle. A final quality check is performed on the refueling vehicle to ensure that there is no problem with the aviation fuel. The refueling operation is checked for safety by going through 19 check points. We provide training and drills to ensure that the operation is performed properly in a limited time in an effort to improve safety and security.

5 Safety System

We handle a large amount of aviation fuel in a disaster management zone, so we are designated as a specified business operator under the Act on the Prevention of Disasters in Petroleum Industrial Complexes and Other Petroleum Facilities. Accordingly, we have a safety management system that places disaster management personnel around the clock to watch for disasters and prevent illegal intruders. In addition, we conduct safety and health activities to prevent industrial accidents and health problems.